4 月 . 19, 2024 14:19 返回目录

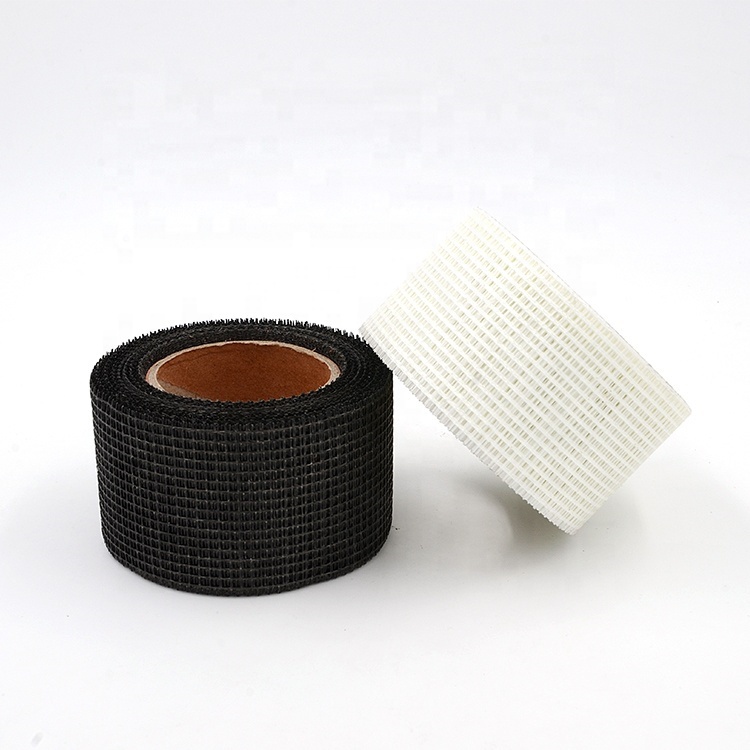

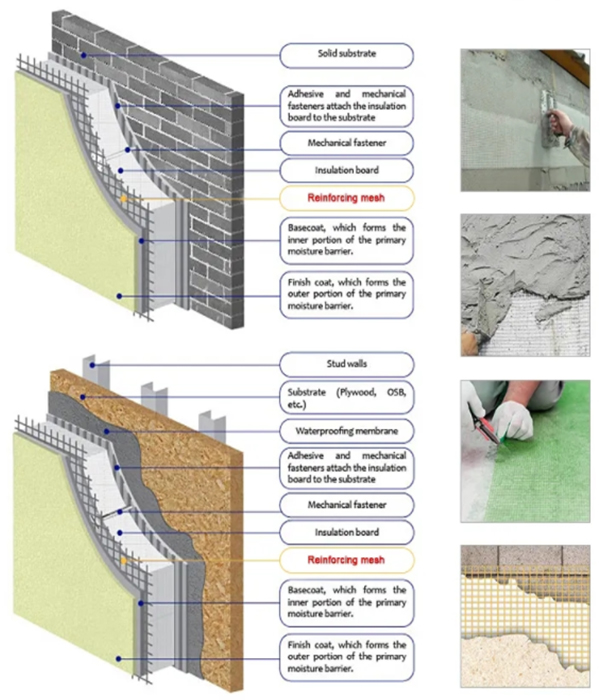

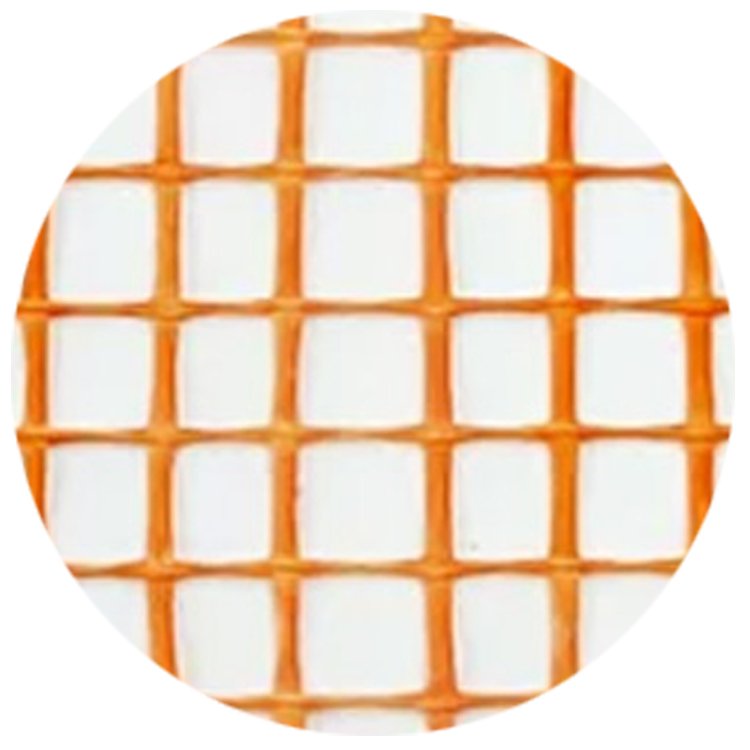

What is fiberglass mesh tape used for? Fiberglass Mesh Tape

Prev:

最新新闻

-

The Ultimate Guide to Fiberglass Mesh Tape for Drywall and Gypsum Board Applications新闻Aug.13,2025

-

The Ultimate Guide to Fiberglass Mesh Tape: Applications, Benefits, and Best Practices新闻Aug.13,2025

-

The Complete Guide to Self-Adhesive Fiberglass Mesh Drywall Tape: Benefits, Uses, and Tips新闻Aug.13,2025

-

Everything You Need to Know About Alkali Resistant Fiberglass Mesh Tape: Uses, Benefits, and Applications新闻Aug.13,2025

-

Comprehensive Guide to Fiber Glass Yarns: Types, Uses, and Leading Manufacturers新闻Aug.13,2025

-

A Comprehensive Guide to Self-Adhesive Fiberglass mesh Tape for Plasterboard and Drywall新闻Aug.13,2025

Products categories