Jun . 28, 2024 12:30 Back to list

Drywall Fiberglass Mesh Manufacturers A Comprehensive Guide

Innovations in Drywall Fiberglass Mesh Manufacturing

In the world of construction materials, drywall fiberglass mesh stands out for its versatility and effectiveness. This humble yet crucial component plays a significant role in ensuring the durability and longevity of walls and ceilings. As such, manufacturers of this specialized product are constantly innovating to meet the evolving demands of the construction industry.

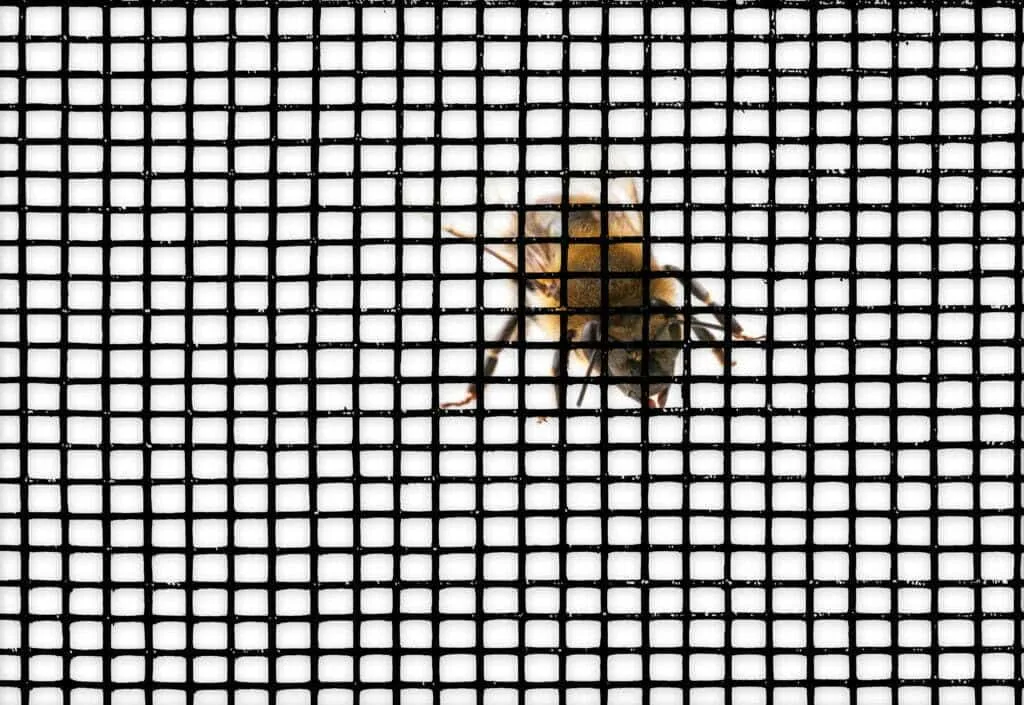

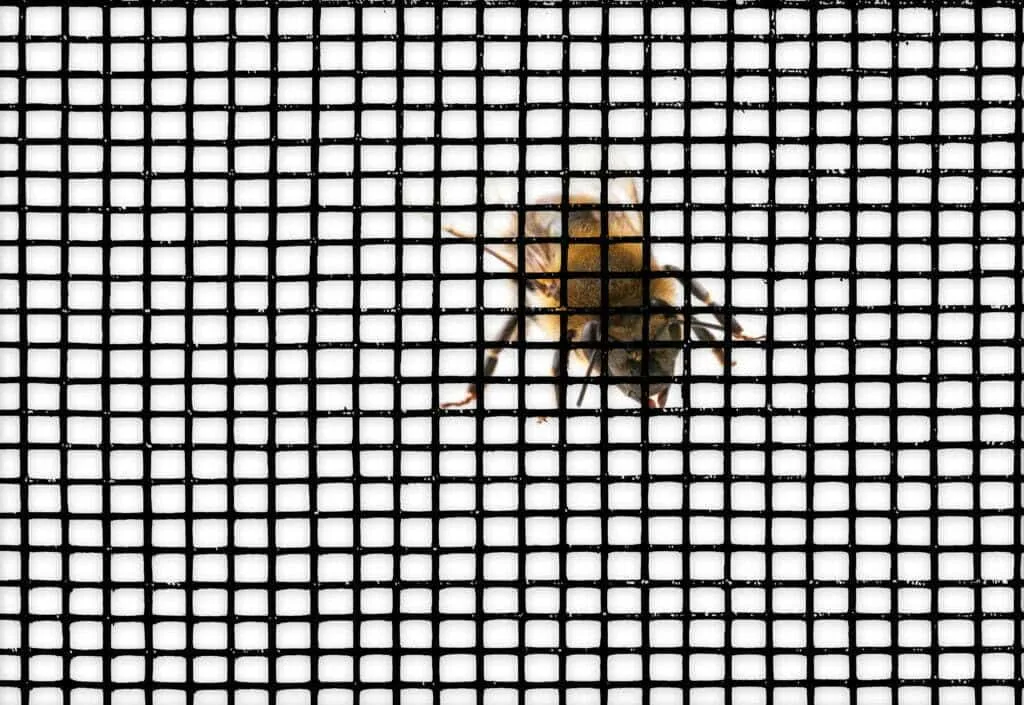

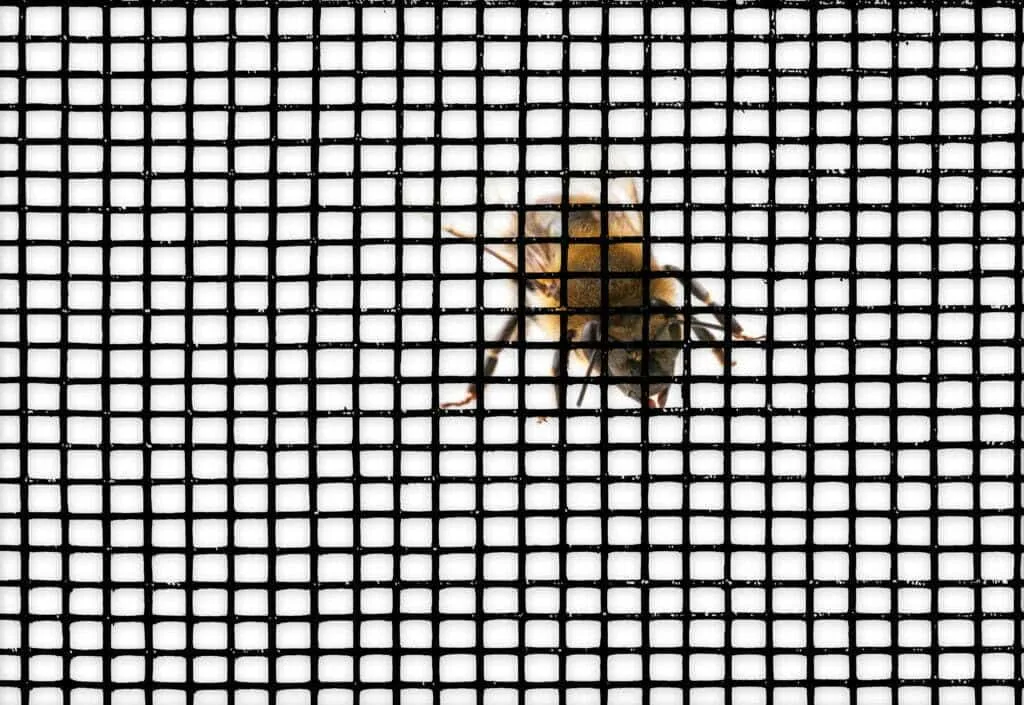

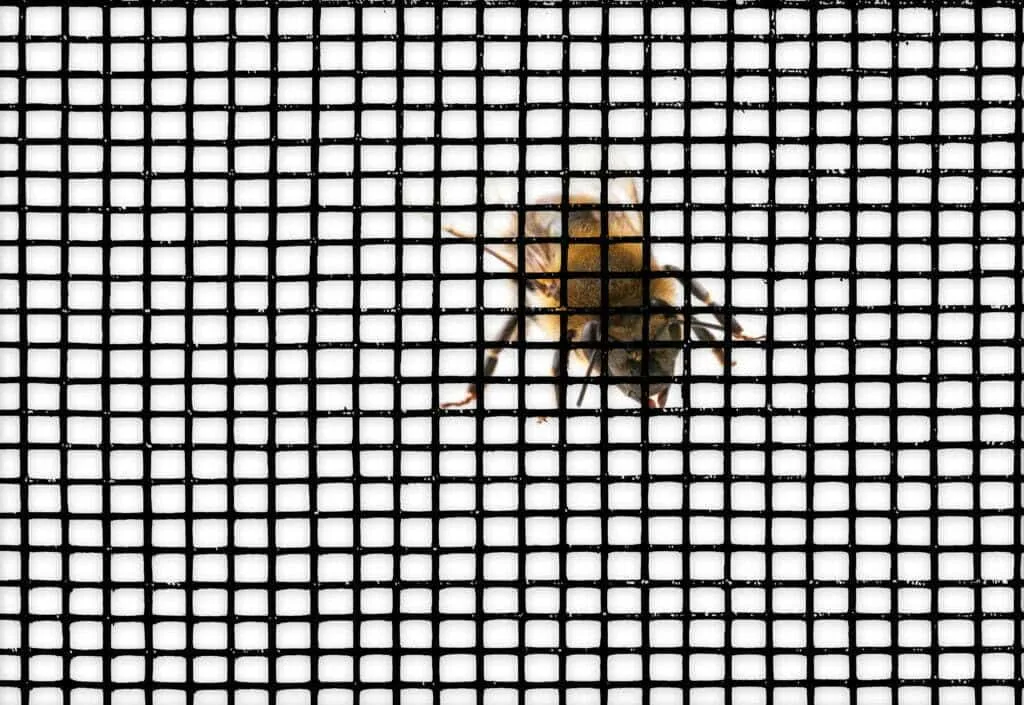

Drywall fiberglass mesh is a type of fabric made from fine strands of glass fiber that are woven together. It is used as a reinforcement material in the joints between sheets of drywall, providing strength and stability while allowing the joint compound to adhere properly. The mesh is also essential for fireproofing applications, as it helps contain the spread of flames and smoke.

Manufacturers of drywall fiberglass mesh have been investing heavily in research and development to improve their products. One area of focus has been on enhancing the mesh's strength and flexibility without sacrificing its lightweight nature. New weaving techniques and advanced materials have led to stronger meshes that can withstand more stress during installation and over time.

Another innovation has been the introduction of mesh varieties designed specifically for moisture-resistant environments. These products feature water-repellent coatings or specialized fiber treatments that prevent mold growth and maintain integrity even when exposed to high humidity levels These products feature water-repellent coatings or specialized fiber treatments that prevent mold growth and maintain integrity even when exposed to high humidity levels These products feature water-repellent coatings or specialized fiber treatments that prevent mold growth and maintain integrity even when exposed to high humidity levels These products feature water-repellent coatings or specialized fiber treatments that prevent mold growth and maintain integrity even when exposed to high humidity levels

These products feature water-repellent coatings or specialized fiber treatments that prevent mold growth and maintain integrity even when exposed to high humidity levels These products feature water-repellent coatings or specialized fiber treatments that prevent mold growth and maintain integrity even when exposed to high humidity levels drywall fiberglass mesh manufacturers. Such advancements are particularly valuable in bathrooms, kitchens, and other areas prone to dampness.

Environmental concerns have also driven manufacturers to explore more sustainable production methods. Recycling programs for old fiberglass mesh have been implemented, reducing waste and conserving resources. Additionally, some companies are experimenting with bio-based resins and alternative fibers sourced from renewable materials like bamboo, which could potentially reduce the carbon footprint associated with conventional fiberglass production.

As technology continues to advance, there is potential for further breakthroughs in drywall fiberglass mesh manufacturing. Nanotechnology might allow for even finer mesh structures that offer superior performance without adding noticeable weight or thickness. Smart materials could be incorporated into the mesh, enabling it to change color when exposed to certain conditions, acting as an indicator for potential issues like water damage or structural stress.

In conclusion, the future of drywall fiberglass mesh manufacturing looks promising, with ongoing innovations aimed at improving strength, durability, environmental impact, and functionality. As these products become more sophisticated, they will undoubtedly contribute to the creation of safer, more efficient buildings that better serve our needs and protect our environment.

drywall fiberglass mesh manufacturers. Such advancements are particularly valuable in bathrooms, kitchens, and other areas prone to dampness.

Environmental concerns have also driven manufacturers to explore more sustainable production methods. Recycling programs for old fiberglass mesh have been implemented, reducing waste and conserving resources. Additionally, some companies are experimenting with bio-based resins and alternative fibers sourced from renewable materials like bamboo, which could potentially reduce the carbon footprint associated with conventional fiberglass production.

As technology continues to advance, there is potential for further breakthroughs in drywall fiberglass mesh manufacturing. Nanotechnology might allow for even finer mesh structures that offer superior performance without adding noticeable weight or thickness. Smart materials could be incorporated into the mesh, enabling it to change color when exposed to certain conditions, acting as an indicator for potential issues like water damage or structural stress.

In conclusion, the future of drywall fiberglass mesh manufacturing looks promising, with ongoing innovations aimed at improving strength, durability, environmental impact, and functionality. As these products become more sophisticated, they will undoubtedly contribute to the creation of safer, more efficient buildings that better serve our needs and protect our environment.

These products feature water-repellent coatings or specialized fiber treatments that prevent mold growth and maintain integrity even when exposed to high humidity levels These products feature water-repellent coatings or specialized fiber treatments that prevent mold growth and maintain integrity even when exposed to high humidity levels

These products feature water-repellent coatings or specialized fiber treatments that prevent mold growth and maintain integrity even when exposed to high humidity levels These products feature water-repellent coatings or specialized fiber treatments that prevent mold growth and maintain integrity even when exposed to high humidity levels drywall fiberglass mesh manufacturers. Such advancements are particularly valuable in bathrooms, kitchens, and other areas prone to dampness.

Environmental concerns have also driven manufacturers to explore more sustainable production methods. Recycling programs for old fiberglass mesh have been implemented, reducing waste and conserving resources. Additionally, some companies are experimenting with bio-based resins and alternative fibers sourced from renewable materials like bamboo, which could potentially reduce the carbon footprint associated with conventional fiberglass production.

As technology continues to advance, there is potential for further breakthroughs in drywall fiberglass mesh manufacturing. Nanotechnology might allow for even finer mesh structures that offer superior performance without adding noticeable weight or thickness. Smart materials could be incorporated into the mesh, enabling it to change color when exposed to certain conditions, acting as an indicator for potential issues like water damage or structural stress.

In conclusion, the future of drywall fiberglass mesh manufacturing looks promising, with ongoing innovations aimed at improving strength, durability, environmental impact, and functionality. As these products become more sophisticated, they will undoubtedly contribute to the creation of safer, more efficient buildings that better serve our needs and protect our environment.

drywall fiberglass mesh manufacturers. Such advancements are particularly valuable in bathrooms, kitchens, and other areas prone to dampness.

Environmental concerns have also driven manufacturers to explore more sustainable production methods. Recycling programs for old fiberglass mesh have been implemented, reducing waste and conserving resources. Additionally, some companies are experimenting with bio-based resins and alternative fibers sourced from renewable materials like bamboo, which could potentially reduce the carbon footprint associated with conventional fiberglass production.

As technology continues to advance, there is potential for further breakthroughs in drywall fiberglass mesh manufacturing. Nanotechnology might allow for even finer mesh structures that offer superior performance without adding noticeable weight or thickness. Smart materials could be incorporated into the mesh, enabling it to change color when exposed to certain conditions, acting as an indicator for potential issues like water damage or structural stress.

In conclusion, the future of drywall fiberglass mesh manufacturing looks promising, with ongoing innovations aimed at improving strength, durability, environmental impact, and functionality. As these products become more sophisticated, they will undoubtedly contribute to the creation of safer, more efficient buildings that better serve our needs and protect our environment. Latest news

-

The Versatile Role of Fiberglass Mesh in Modern ConstructionNewsJun.09,2025

-

The Essential Role of Alkali Resistant Fiberglass mesh Tape in Modern ConstructionNewsJun.09,2025

-

Strengthening Walls and Joints with Fiberglass mesh Tape SolutionsNewsJun.09,2025

-

Fiberglassmesh Tape Solutions for Stronger Walls and Cleaner FinishesNewsJun.09,2025

-

Fiberglass Reinforcement Mesh: A Modern Essential for Durable FinishesNewsJun.09,2025

-

Enhancing Construction Durability with Self-Adhesive Fiberglass Mesh SolutionsNewsJun.09,2025

Products categories